Thermal transfer ribbons are essential consumables in thermal transfer printers. Selecting the right ribbon is crucial for ensuring high-quality prints and operational efficiency. Here’s a guide to understanding the different types of ribbons available and tips for choosing the best one for your specific printing needs.

Types of Thermal Transfer Ribbons

Thermal transfer ribbons can be categorized based on their materials, which primarily include:

Name | Raw Materials | Features | Suitable Applications |

Wax | Wax and Carbon Powder | Clear printing results, cost-effective, high density and sensitivity | Ideal for coated art label: price tags, shipping labels, product labels |

Wax & Resin | Wax and Resin | High resolution and versatile; excellent printing results | Suitable for coated art label: compliance labels, batch labels, ESD labels, product ID labels |

Resin | Synthetic Resin | High durability, wear resistance, high-temperature resistant, excellent printing quality | Best for matte sliver: jewelry labels, industrial product labels, asset management labels |

Key Factors for Choosing the Right Ribbon

Ribbon Width

Select a ribbon width that is at least 10mm wider than your label paper to effectively protect the printer head.

Ribbon Size

Check the inner diameter of the ribbon core and ensure it fits your thermal transfer printer.

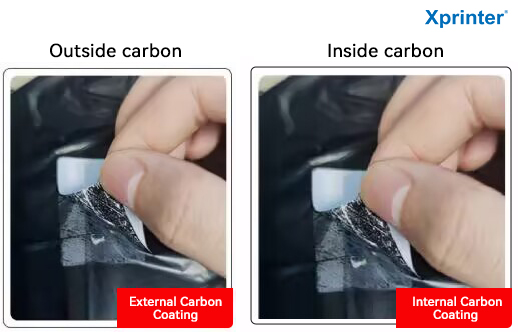

Ribbon Winding Direction

Ribbons come in two winding styles: inside wound and outside wound. You can test the ribbon by sticking a label with adhesive to it and observe if there is carbon powder sticking up. Ensure it’s compatible with your printer.

Printing Speed

Different ribbons perform different at varying speeds. For high-speed printing, ribbons should also selected with high sensitivity. If printing at slower speeds, standard sensitivity ribbons could be enough.

Label Material

Wax ribbons are typically suited for paper labels, while resin ribbons are better for synthetic materials. Assess your label type before making a selection.

Durability and Environmental Considerations

Consider the durability and environmental requirements for your labels. For labels that need to be water-resistant, abrasion-resistant, or chemically resistant, resin ribbons are recommended to maintain readability in harsh conditions.

Conclusion

Choosing the right thermal transfer ribbon is essential for achieving optimal printing results. By understanding the types of ribbons available and considering key factors such as size, width, winding direction, speed, label material, and durability requirements, you can make an intelligent decision that meets your specific printing needs. Whether you need clear price tags or durable asset management labels, the right ribbon can make all the difference in your labeling projects.

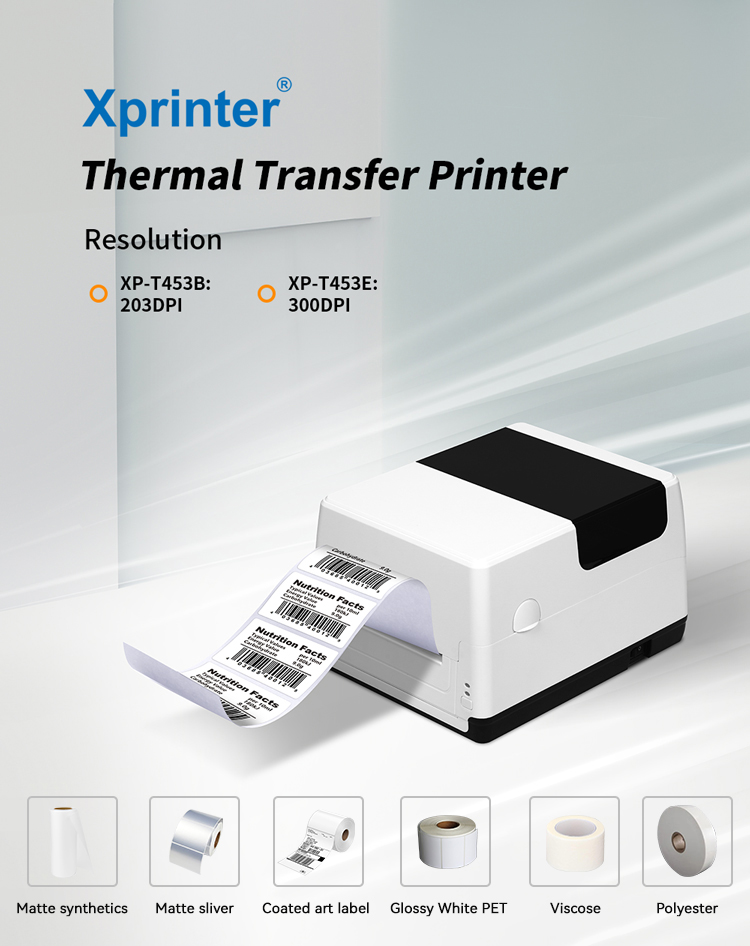

Xprinter provide comprehensive label and barcode printing solution, including top-quality thermal transfer printers and ribbon materials tailored to your needs. Our thermal transfer ribbons are rigorously tested for excellent compatibility with a wide range of label materials, including matte synthetics, matte sliver, coated art label, Glossy White PET, viscose, and polyester. Explore our range of advanced printing technologies to enhance your label printing experience. Contact our barcode printing experts today to discover how we can support your business with reliable and efficient printing solutions!

Copyright © 2026 Xprinter | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.