The non-drying label material selection and purchasing guide a _ printing equipment problems

as an emerging force in the printing industry, self-adhesive label printing become nearly two years in the industry talk about more topics. Remove the application and development of the printing process itself, mature and perfect, the whole outside of the supply chain also gradually enrich and perfect. For the printing cost, how to choose a good supplier, become a printing company must face the topic, because raw material takes up quite a part of the printing cost. In this paper, the selection of the non-drying label materials, terminal application, analyzed the choice of suppliers, to make the label printing company to obtain the optimal cost-effective products.

a, about the non-drying label materials

at present, many different kinds of self-adhesive label materials, mainly from different stickers of three components, namely: the surface material, pressure sensitive adhesive ( The binder) And substrate ( Commonly known as for silicone coating can be away from the substrate) , different surface, pressure sensitive adhesive, substrate material combination can be a lot of self-adhesive label materials.

non-expert users often only pay attention to the choice material, because it can directly show the design, and visual effect. In fact, the high quality self-adhesive label materials instead of the most important is hidden in the face of adhesive and the substrate. After all the label before the finished products, the merits of the surface material easily in the pre-press, printing and finished goods inspection cengcengbaguan, users suffer less; And the glue is vulnerable to label or use environment ( Temperature, humidity, etc. ) By post objects, the influence of different characteristics also have different options for the adhesive.

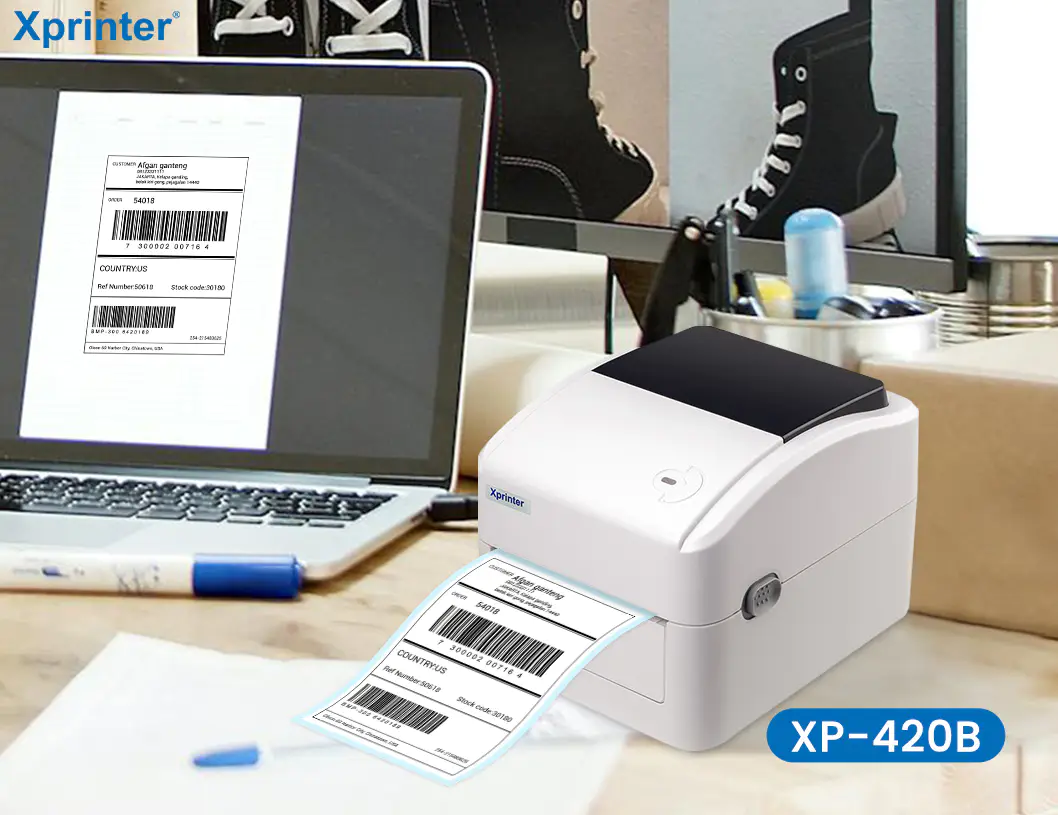

usually in labeling, or and posted content joint for a period of time, even after some time will expose the glue problem, thereby causing loss to the user, the largest serious glue will damage the printing equipment; Low substrate or silicone coating, will also be in die cutting, label, print only when exposed to wear, fly, no logo, paperboard, such as use, will cause bigger loss to the user.

on the market the main characteristics and the types of the pressure sensitive adhesive were as follows:

1, the solvent adhesive: being dissolved in solvent, economy, and is more adapt to the use environment, but a greater toxicity to human body. Developed countries have been banned in Europe and the us at present in China is still a large number of used in direct contact with human body wet wipes, sanitary napkin, daily chemical products, and even food labels.

2, emulsion adhesive: dissolve in water, harmless to the environment, suitable for most operations;

3, hot melt adhesive: prefabricated adhesive;

4, UV glue, is a kind of new technology, UV light curing.

most high-grade self-adhesive label materials adopt type emulsion pressure sensitive adhesive and hot melt adhesive. For printing enterprise, in numerous products to make a choice is not an easy thing. Because of different adhesives have different advantages and disadvantages, and correspond to different surfaces and the environment, so look for the most commonly used product is printing the common interests of enterprises and suppliers, as a widely used product is easy to produce and have stable quality, the same as the non-drying label material supplier for printing enterprise to save storage space and time.

pусский

pусский  Português

Português  العربية

العربية  Français

Français  Español

Español  (+86)-0756-3932978

(+86)-0756-3932978