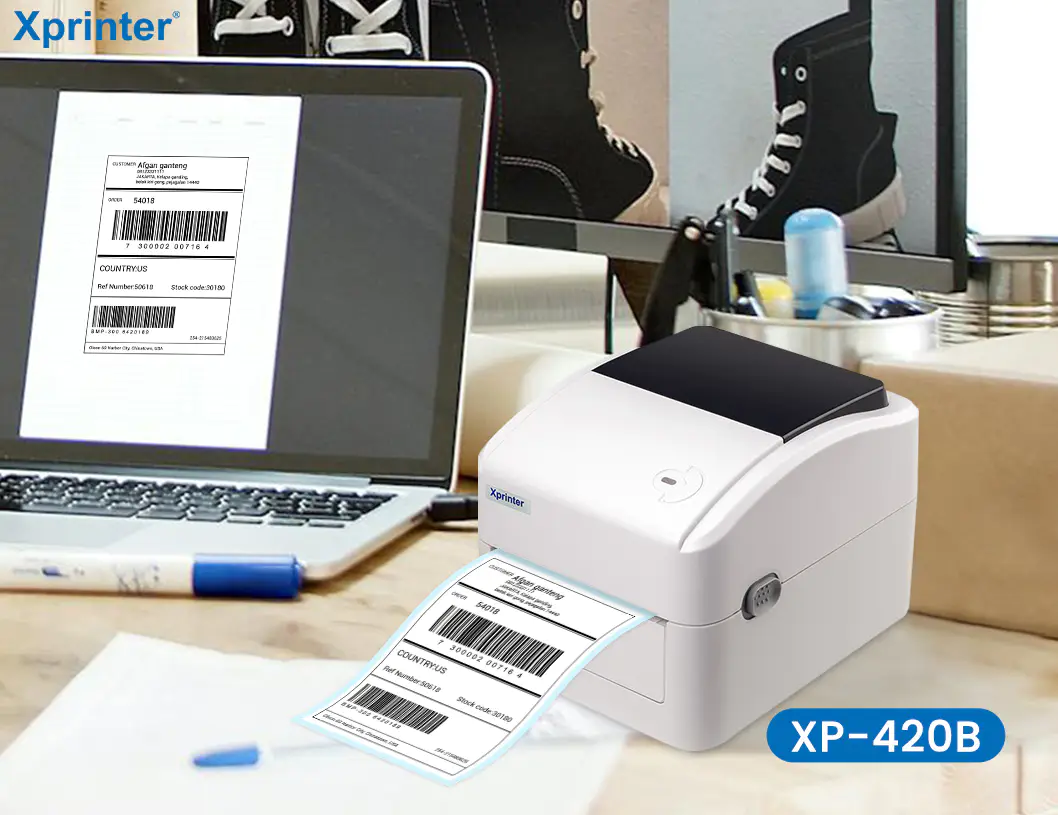

Bar code printer maintenance knowledge _ printing devices

in order to ensure that the barcode printers print quality and good performance for a long time, the bar code printer maintenance on a regular basis to maintain knowledge need to know, the more frequently the barcode printers use, the more you should often clean, ( Don't use often = weekly cleaning often use = clean every day) Now, let me make a brief introduction for you, how to correctly the maintenance of the bar code printer.

1, to prevent direct contact with the print head nail scratch etc.

when a barcode or outline/line appear in the graphical print effect is not consistent, may be print head with dirt needs cleaning, should be time to clean the print head. In the print head cleaning homework do not necessarily have to closed the power and in clean condition.

2. The print head cleaning

turn off the power of the printer, the print head turns up, remove the foil, paper label, with dip with a small amount of alcohol ( 80%) Cotton swabs, gently clean the print head until clean, then quietly wipe with clean cotton print head. Please don't use metal objects ( Like a knife, screwdriver, etc. ) Don't contact with the hand knock against the print head, the print head.

3, roller clean

after cleaning the print head, with dip 75% alcohol swabs (a small amount of Or cotton) Cleaning roller. Way is by hand rolling drum, while wiping, after waiting for clean and dry. The above two steps clean distance is usually three days, if the bar code printer use frequently, once a day.

4, drive system, and clean inside the case

because usually label paper as adhesive, the adhesive and the simple transmission shaft and channels, plus there are dust, directly affect the print effect, so need often clean. Usually 2 times a week, way is to use dip with alcohol swabs ( Or cotton) Each wipe the drive shaft, channels, and appearance and the dust inside the chassis, after clean, dry.

5, sensors, cleaning and other considerations

sensor contains the ribbon sensor and the label sensor, usually 1 - 3 months clean once, on the way to go is electric fan blowing such as sensor dust and foreign body power supply ground wire in case by static overload, abnormal voltage fluctuations damage to print head and machine main board.

the printer can't charged plug, hot-swappable simple burn out printer motherboard. Closed before you plug cable power supply.

the printer usually protection is directly related to the use of the print head life, such as protection of owe good shorten the print head using life is simple, and even damage the print head and machine main board.

barcode printers print temperature keeps in 10 - Between 24, not too high, otherwise easy to reduce the service life of the print head, pay attention to the collocation of carbon belt and labels, generally is coated with wax base carbon belt, synthetic paper with half a tree or the tree carbon belt. In addition, the label paper pay attention to keep flat, do not make its rugged, otherwise, the print head is easy to wear.

the above is the entire content of this article, if you want to know more information of bar code equipment, welcome you through WeChat, telephone, website, etc to consult with our company, we will wholeheartedly for your answer, make you satisfied.

pусский

pусский  Português

Português  العربية

العربية  Français

Français  Español

Español  (+86)-0756-3932978

(+86)-0756-3932978