Bar code printer technology makes the logistics enterprise fast one step _ printing devices

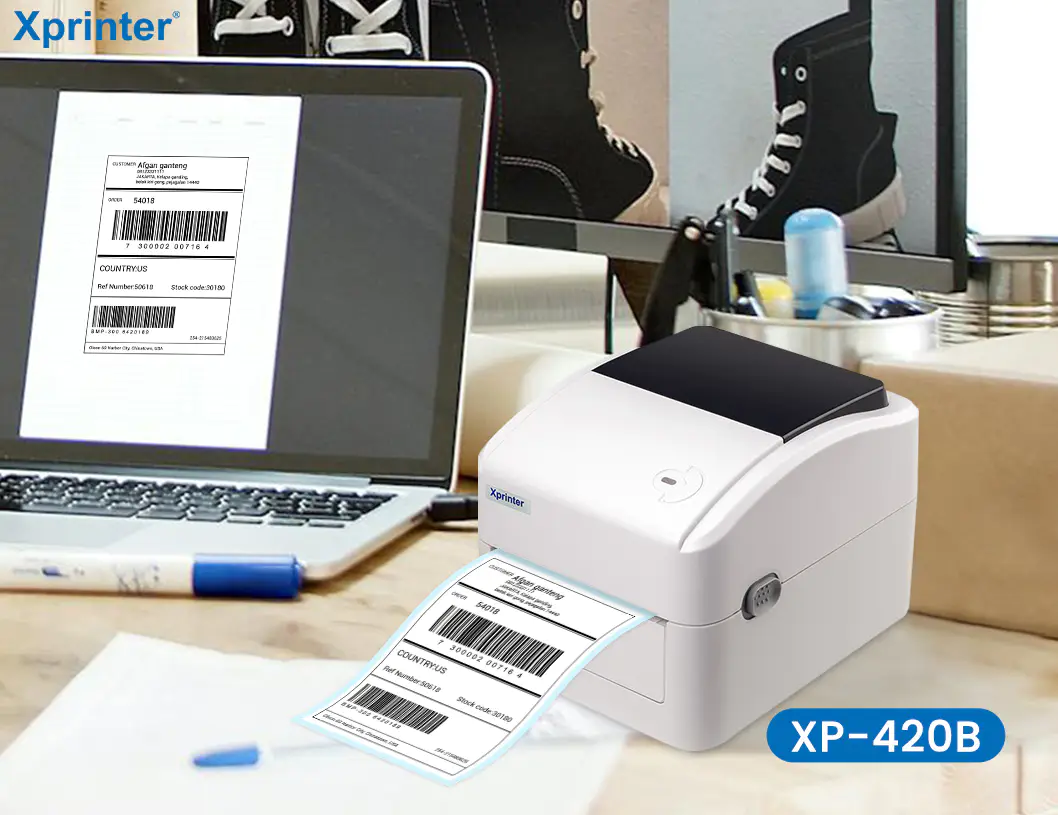

at this stage as the rise of the logistics enterprises in succession, bar code printer technology as a link in modern logistics system, the position increasingly highlighted. As a logistics system is an important technology, its advantages are those? Of (among) all the automatic identification technology, bar code the most adapted to the rapid and large quantities of information collection, the most able to adapt to high speed large quantitative and logistics requirements, it can greatly improve the efficiency of logistics, is a computer management system indispensable beginning with the electronic data interchange (edi) technology. The emergence of bar code, changed the traditional manual entry of data automatic identification method for the machines, as to realize automatic data collection and input of a special code. Bar code has the following main advantages: 1, the high accuracy: by scanning bar code input data, its accuracy is much higher than the keyboard input. Keyboard input error rate is one over three thousand, and bar code input error rate is one over three million. 2, input speed: bar code input speed 20 times the speed of the keyboard input. 3, make easy: bar code is easy to make, for printing technology, equipment and materials, etc. No special requirements. 4, equipment, economic and practical: barcode label making machine unit is simple, high reliability, easy to operate, the price is cheap. Based on the advantages of the bar code above, making all the exchange of information, physical distribution and transmission greatly accelerated, many department stores, supermarkets, warehouse management, using the barcode system. The application of the bar code to all walks of life, especially the rapid development of logistics, warehousing, Courier industry, provides the prerequisite. A typical logistics bar code management system should include transportation, warehousing, shipping, receiving, etc of automation management. Barcode as unique identification of the point throughout the entire logistics process, plays an important role in ties in every link. Items of replenish onr's stock, operators use barcode data collector to identify the goods the original identity, customer code, quantity, shelves and other information of the input, and then put the goods in small transport vehicle ( If items are not bar code, bar code data collector will default to an empty) 。 For all the items to the warehouse after the login, the data collector on the communication interface, drive the printer will print into the storehouse goods identification, listing.

goods delivery: the operator first with the barcode data collector scans goods identification, enter the client code, quantity of the goods, such as train route information, after the completion of the operation, using printer to print out the goods out of warehouse list, and then the data through the network to update the database information. Finished goods delivery work automatically. Item management, query: the application of barcode system in warehouse management, asing if is tailored for general, very easy to solve the problem of traditional warehouse management, make the whole management in an orderly way, clear. Using barcode for item management items. Each kind of different specifications, models of items with the different bar code identification, the integration of barcode data collector and computer aided identification, input devices, implement a yard.

items shall be carried out in accordance with the coding rules, logo. Query, check the goods, only need to use barcode scanner to scan items code, the database server will conform to the condition of all items details submitted. , of course, can also be scanned into the warehouse receipt or out of the warehouse receipt barcode, query the consignee of goods and related information, also can understand the company's operating at the same time, even will rely on advanced network dynamic query and track the whole process, all the work can be management to the barcode.

pусский

pусский  Português

Português  العربية

العربية  Français

Français  Español

Español  (+86)-0756-3932978

(+86)-0756-3932978