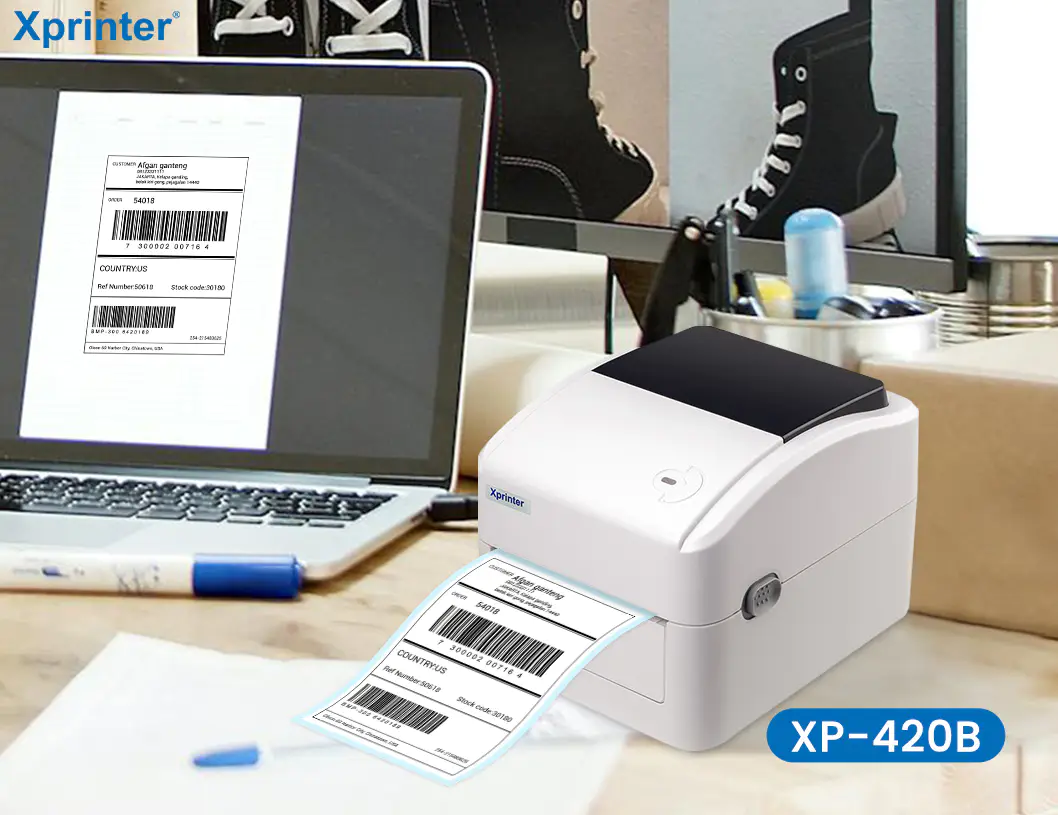

Horizontal pushing paper printers use skill analysis _ printing equipment problem

by:Xprinter

2020-06-06

Analysis of horizontal pushing paper printers use skills 1, pay attention to the power of the printer.

Printer and computer equipment is very afraid of strong magnetic field, so should try to avoid when using a printer printer with high power capacitive or inductive electrical appliances to use the same multi-function power socket, and put the position also stay away from these appliances (

As a high power motor DJONZMYOJQIZIWBGKJPY motivation of electrical appliances, etc. )

。

2, pay attention to the printer display environment.

Dot matrix printer work environment as far as possible to clean dust and to ensure as far as possible, and be sure to stay away from with acid, alkali corrosion, put the printer workbench must be stable and no vibration, especially pay attention to is not to put any items on the printer, and to avoid these items fall into the internal influence of mechanical part of the machine works, and even cause serious trouble!

3, to clean the printer and strengthening lubrication work regularly.

Printer is mechanical products, so we should often use small hair brush and bellows to sweep, blow the paper scraps and dust scattered inside the printer, but also to maintain the appearance of the printer clean, with dirt and stains should be timely to wipe off in order to avoid entering the printer in the future, especially the word car guide shaft and gear system all must keep clean and no dust & ndash; as far as possible

—

Can wipe gently with soft cotton cloth or gauze masks word car guide shaft, wipe again after filling a small amount of middle and senior lubricating oil.

If word car guide shaft too dirty words are easy to make the word car mobile not free, in this case, if the working time slightly longer might make the word car driver circuit heating until severe burn out.

4, timely replacement of printing ribbon.

Printer ribbon in use after a period of time, the color becomes shallow, then remember to timely replacement ribbon, try not to force adjusting stitch or aggravating print, do so it would be easy to cause breakage faults, of course, you'd better don't use old recolor ribbon, because the old ribbon majority has been napping, its spinning and weaving density had been destroyed, so after the old ribbon using heavy oil is extremely easy to block print needle guide hole, so I advise you not to corrupt a cheap and cause unnecessary trouble, and when something is hanging ribbon to replace in time so as not to hang up it also print needle.

Note: the author is strongly recommended that you must change the good quality ribbon, and as far as possible to the shop with good credit to buy, why the author will no longer say more.

5, be sure to properly adjust the clearance between the print head and print roller.

Almost all of the dot matrix printer has a paper adjusting switch, when we print different layer of paper, be sure to select the appropriate control rod position, such as we want to print a layer of paper, adjusting lever should be placed in position 1 or 2, when we want to print two layers of paper, adjust the position of the bar should be placed in 2 or 3, such as this, the author will no longer enumerate, as for the control rod location should be set according to the printer operation manual, just to abide by the principle of ningyuan keep away, another printer for new bought or new in the print head, thick paper should be switch is set to a few bigger, because the new print head and print pin has not been wear and tear, it is best to thick paper switch set in the position of band 3 or 4 files, such as printers use after a period of time then slowly will switch on the right place.

Custom message

pусский

pусский  Português

Português  العربية

العربية  Français

Français  Español

Español  (+86)-0756-3932978

(+86)-0756-3932978