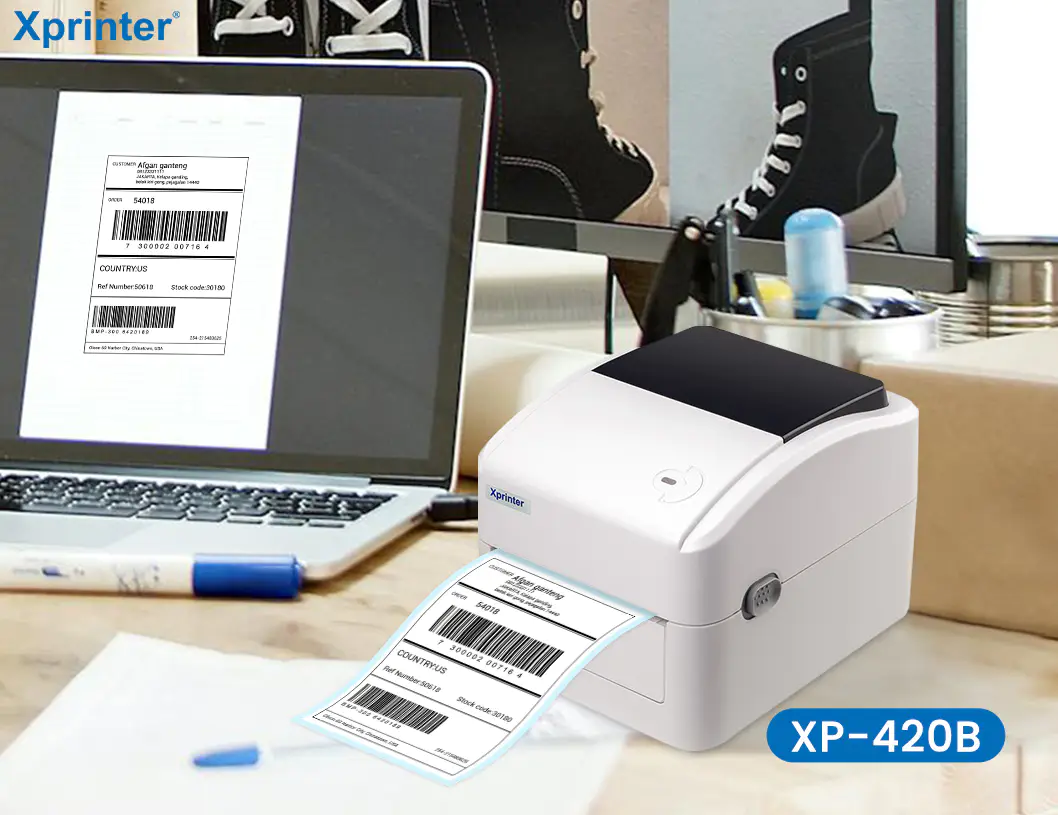

Bar code printer maintenance and regular maintenance method _ printing devices

takeaway: label bar code printer is a kind of special printers, bar code label printer maintenance and regular maintenance, to ensure the quality of the bar code printer and good performance for a long time, the more frequently the barcode printers use, the more the often clean.

so, bar code printer to how to carry out daily maintenance and maintenance regularly?

1。 The print head cleaning

to regular, regular cleaning the print head, can use cotton swabs and alcohol cleaning tools. Turn off the power of the bar code printer, please keep the same direction when wiping ( To avoid back and forth to wipe dirt residues) , will be the print head, remove the foil, paper label, with dip cotton swabs with the print head cleaning fluid ( Or cotton) , gently clean the print head until clean. After gently wipe with a clean cotton print head. Keep the print head clean way can get good printing effect, extend the service life of the print head is the most important thing.

2。 Rubber roller cleaning and maintenance

to regular, regular sex clean bar code printer rubber roller, cleaning tools can use cotton swabs and alcohol, keep the rubber roller clean, also is in order to get good printing effect, and extend the life of the print head. In the process of printing label paper will leave a lot of powder on the rubber roller, if not timely cleaning, will hurt the print head; Glue stick with for a long time, if you have some uneven wear or may also affect printing and damage the print head.

3。 Drum cleaning

after cleaning the print head, with cotton swabs dipped 75% alcohol ( Or cotton) Cleaning roller. Method is the roll by hand, while scrubbing, after being a clean, dry. The above two steps of cleaning intervals are generally three days, if the barcode printers use frequently, best once a day.

4。 Transmission system clean and clean inside the case

because general paper labels for the stickers, the glue is easy to stick on the drive shaft and channels, plus there are dust, will directly affect the printing effect, it needs to clean frequently. Usually once a week, method is to use dip with alcohol swabs ( Or cotton) Scrub each drive shaft, the surface of the channel, and the dust inside the case, after clean, dry.

5。 Sensor cleaning to keep the sensor clean

sensor including labeling of ribbon sensor and the sensor, the position see manual, usually once every three months to six months to clean, the method is to use soak with alcohol swab swab sensor head, clean, dry.

6。 Into the clean paper guide

guide groove, generally there will be no big problem, but sometimes people or label quality problem caused by label stick in the guide groove inside, it also need to clean it in time.

7。 Temperature keeps in 10 - printer 24 degrees between

temperature not too high, otherwise easy to reduce the service life of the print head, pay attention to the collocation of carbon belt and labels, generally is coated with wax base carbon belt, synthetic paper with a tree or the tree carbon belt. In addition, the label paper pay attention to keep flat, do not make its rugged, otherwise, the print head is easy to wear.

pусский

pусский  Português

Português  العربية

العربية  Français

Français  Español

Español  (+86)-0756-3932978

(+86)-0756-3932978